Knits vs. Wovens vs. Nonwovens: What’s the Difference?

When you’re looking for and working with fabrics, you must be able to distinguish the differences between knit versus woven versus nonwoven fabrics. The names of these fabric types are somewhat indicative, but let’s explore each of these fabrics a bit more in depth with some examples and examine the processes by which they’re made.

Knit Fabric

Knitting is the process of forming a fabric by interloping yarn. One can do this either by hand or by machine, as the interloping process is the exact same either way. Because of how loose a knit fabric’s structure is, knit fabric is capable of stretching more in comparison to woven and nonwoven fabrics. However, because of this loose structure, the structure might tighten up under the high temperatures of a clothes dryer or with the mechanical action of a laundry machine’s faster spin cycles. To eliminate this shrinkage, many manufacturers simply shrink their knit fabrics in advance, allowing the knitter to properly compensate by knowing how much fabric they’ll actually need for their garment. Another aspect of knit fabric to consider is that, because it’s looped around itself, pulling on a single strand can cause the entire piece to unravel.

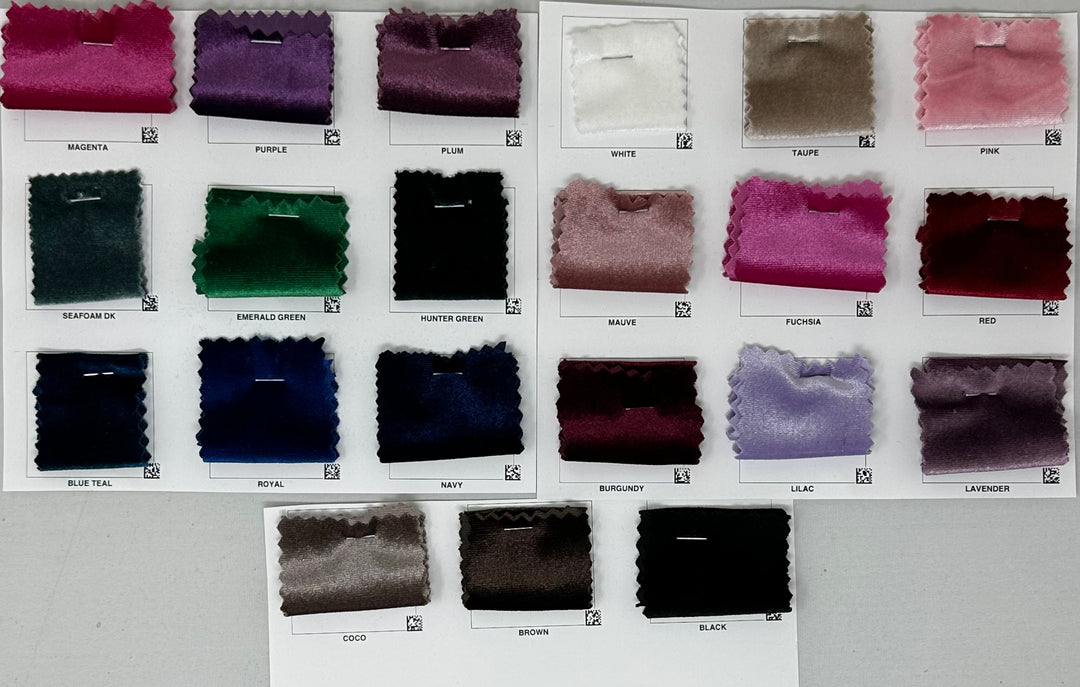

Noted for their comfort and warmth, knitted fabrics are perfect for garments suited for colder climates. They also come in a wide variety—from solid-colored to leopard-print knit fabric—so your creativity will never be limited.

Woven Fabric

Woven fabrics are exclusively produced on looms. The loom joins two different sets of yarn by weaving them between each other in a perpendicular fashion. One set of yarn, the “warp,” runs the length of the other yarn, while is called the “fill” or “weft” yarn. The loom raises the warp yarn up and down to create a shed, while the weft yarn is placed in the shed parallel to the warp yarn. Once the shed closes, the yarn alternates up and down once more to create another shed and to allow another weft yarn to be placed within. Depending on what yarns are opened up or pulled down in the shed, the loom can create fabric constructions such as twill weave or plain weave.

In comparison to the other fabric types, woven fabrics are more durable when washed, and they can be finished with different attributes such as water repellence or fire resistance. Because this durability comes from the yarn being woven so tightly, it’s not capable of stretching very much unless you add elastomeric fibers such as spandex to the yarn.

Nonwoven Fabric

Nonwoven fabrics are a bit peculiar in the way they’re formed. These fabrics can be created through a mechanical bonding technique called fiber entanglement; chemical bonding with glue-like compounds that bond the fibers together; or thermal bonding, in which heat is applied to fibers with a low melting point to melt them together. In comparison to woven and knit fabrics, nonwoven fabrics aren’t very durable, and they’re much lighter and weaker. They also lack the memory that other fabrics have, meaning that if you bend them, they won’t not retain their position or leave much of a “pucker.” This makes them poor choices for garments—rather, they’re suited for single-use products such as wipes, feminine hygiene products, medical products, disposable diapers, and other similar product that you only expect to use once.

Production Steps for Knits

Now that you better understand the difference between knit versus woven versus nonwoven fabrics, let’s compare the production steps for each fabric type. For knit fabrics, the production process can be broken down into six parts. First is simply acquiring the bale of staple—“staple” referring to the specific length of a textile’s fibers. Next, the fibers are mechanically opened and cleaned before being formed into a web and drawn out so that the fibers can be spun into yarn. Once the yarn has formed, one can finally knit it into fabrics to be used in garments. This process can produce 2 to 16 yards of fabric per minute, which makes it the second-fastest of the three varieties.

Production Steps for Wovens

The production process of woven fabric is by far the lengthiest. It can be broken down into eight steps. Five of these steps are the same as those in the knit fabric process, starting with a bale of staple fibers and ending with the creation of the yarn. However, the yarn is then warped. Warping yarn refers to the process of combining yarns from different cones into a single sheet while maintaining their elongation and uniformity. This warping process decreases the likelihood of low-end breakage during the weaving process. After being warped, the yarn goes through a protective process called sizing to prepare it for the weaving process. During the sizing process, the yarn is coated with a synthetic or natural adhesive that makes it more durable. After the sizing process is complete, the yarn is finally ready for weaving.

Woven fabrics are typically produced at rates of 0.5 to 6 yards per minute, which makes it the slowest process of the three.

Production Steps for Nonwovens

Nonwoven fabric takes the least amount of time to produce, given that there are only four steps in the production process. After the bale of staple fibers has been mechanically opened and formed into a web, the bonding process takes place by melting the fibers together with heat. This process is simple enough that staple fiber nonwoven fabrics can be produced in amounts as large as 100 to 400 yards per minute. This speedy construction is largely why nonwoven fabrics make the perfect materials for single-use products: they can be easily mass produced and replaced to keep up with demand. This mass production also makes them very cheap to produce in comparison to knit and woven fabrics, allowing the products that use nonwoven fabrics to remain cheap and affordable.

Now that you’re armed with the knowledge of why these fabrics have the properties they do, we hope you’re better prepared to find the fabric that best suits your project.